Why Nylon Films Matter in 2026 Manufacturing

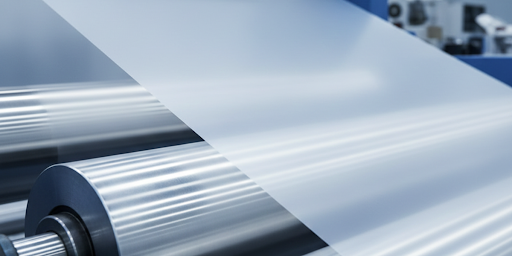

High-performance nylon films are entering a new phase. Once used mainly for niche or premium applications, they are now becoming essential across various industries, including food, medical, pharmaceutical, and industrial manufacturing. As brands demand stronger barrier protection, longer shelf life, and higher durability, polyamide (PA) films, especially nylon 6 and nylon 6/66 blends, are gaining momentum.

These films deliver the qualities manufacturers value most:

- strong puncture and abrasion resistance

- excellent oxygen and aroma barrier

- clarity and printability

- heat resistance for retort and demanding processes

- compatibility with complex multi-layer structures

At the same time, sustainability goals and recyclability pressures are reshaping how nylon films are engineered. Innovations in thinner gauges, cleaner formulations, and renewable or circular polyamides are redefining the next generation of high-performance films.

With over 50 years of experience, M&Q Packaging helps manufacturers navigate these changes by providing engineered nylon films designed for demanding environments across the food processing, medical, aerospace, and industrial markets.

The State of Nylon Films Today (2024–2025)

Demand for nylon films grew steadily through 2024 and 2025 as manufacturers sought stronger barriers, improved mechanical strength, and better clarity for high-value packaging.

Nylon 6 remains the most widely used material because of its versatility and cost efficiency. Nylon 6/66 blends, which M&Q offers, support higher temperature resistance, improved durability, and long-term stability. These qualities make them ideal for premium or technical film structures.

Across the industry, nylon films continue to serve three major sectors:

- Food packaging: vacuum pouches, cook-in bags, fresh proteins, retort packaging

- Medical and pharma: sterilizable films, chemical-resistant barrier structures, cleanroom applications

- Industrial and electronics: abrasion-resistant liners, moisture barriers, specialty protection

These applications rely on nylon’s combination of barrier performance and toughness, capabilities that are difficult to match with polyolefin-only structures.

Key Innovation Drivers Shaping 2026

1. Thinner, Stronger Film Designs

Manufacturers are aggressively down-gauging. New PA6 and PA6/66 formulations support thinner films without sacrificing strength or barrier, helping reduce material use and shipping weight.

2. Cleaner, Safer Film Formulations

Regulations are accelerating the shift toward PFAS-free, phthalate-free, and solvent-reduced film structures. These changes are particularly important for food, medical, and pharmaceutical applications.

3. Renewable and Circular Polyamides

Bio-based and bio-circular nylon options are entering the market. These materials lower carbon impact while maintaining strong mechanical and barrier performance. They are becoming an attractive option for brands with ambitious sustainability goals.

4. Process Automation and Digital Quality Control

Extrusion and film conversion lines continue to evolve with real-time gauge monitoring, predictive maintenance, and digital traceability. These upgrades support consistency, reduce waste, and improve sustainability reporting.

5. Smarter Multilayer Architecture

While recyclability challenges remain, manufacturers are exploring simplified PA and PE structures, compatibilizers, and mono-material strategies to align with upcoming recyclability standards.

What Manufacturers Need to Prepare For

To stay competitive in 2026, manufacturers should focus on:

- Optimizing material selection: Nylon 6 for versatility and nylon 6/66 blends for high-performance or high-temperature environments.

- Rethinking film structure design: Simplified layers and recycle-ready configurations will grow more important as regulations evolve.

- Modernizing equipment: Better gauge control, cleaner formulations, and more automated workflows support performance and sustainability.

- Strengthening supply-chain resilience: Diversified resin sourcing and alternative PA grade qualification help reduce risk.

- Increasing transparency: Certifications and traceability will matter more as sustainability claims face greater scrutiny.

M&Q’s nylon, polyester, and elastomer films support these needs by offering durable, heat-resistant, FDA-compliant materials in multiple forms, including sheets, tube stock, V-fold, bags, and thermoforming webs.

Conclusion

By 2026, nylon films will be shaped by smarter material engineering, sustainability-driven design, and more advanced manufacturing practices. Companies that adapt early and partner with experienced suppliers like M&Q Packaging will be positioned to lead as the industry moves toward high-performance, lower-impact materials that balance strength, barrier protection, and environmental responsibility.